We Are RFcore

We design and manufacture MMICs, HPAs, and Customized systems.

Products & Services

We provide high-quality RF Solutions.

- High Power Amplifiers

Available in operating frequencies from HF to Ku-band with standard output powers ranging from 2 to 1000 watts. Standard functions include FWD/RVS detector, Mute, Temperature monitoring, VSWR alarm with protection, Over temperature alarm with protection and auto-recovery, Over voltage protection, ALC, AGC, and Current monitoring.

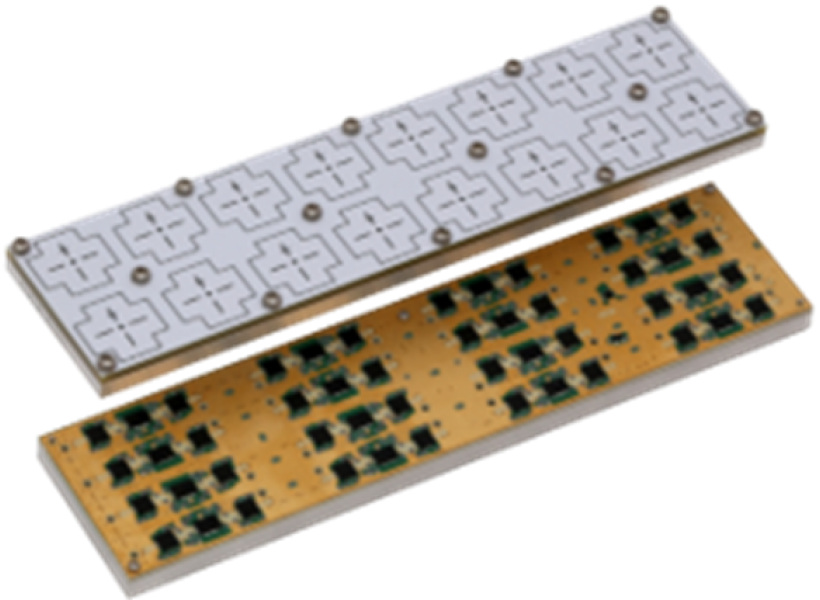

- Phased Array RFFE

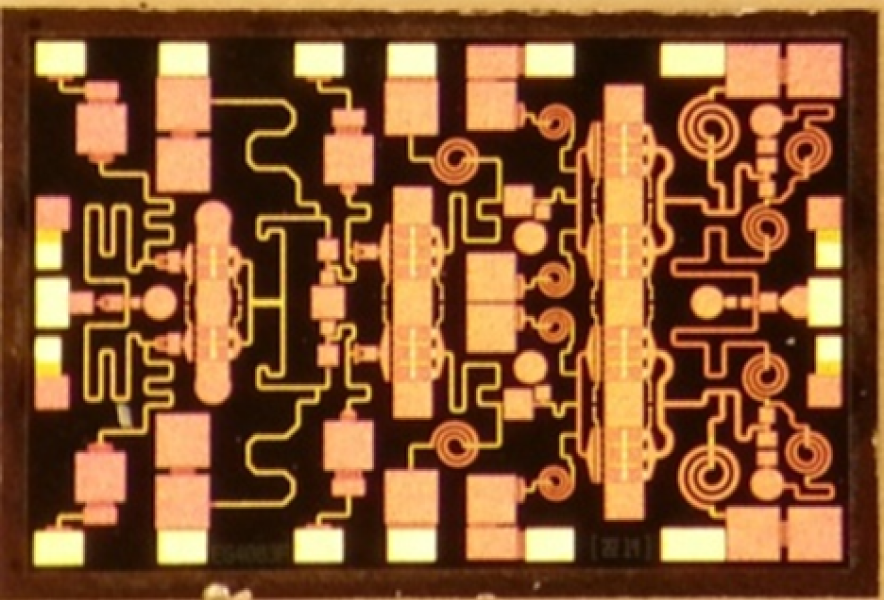

- MMIC Solutions

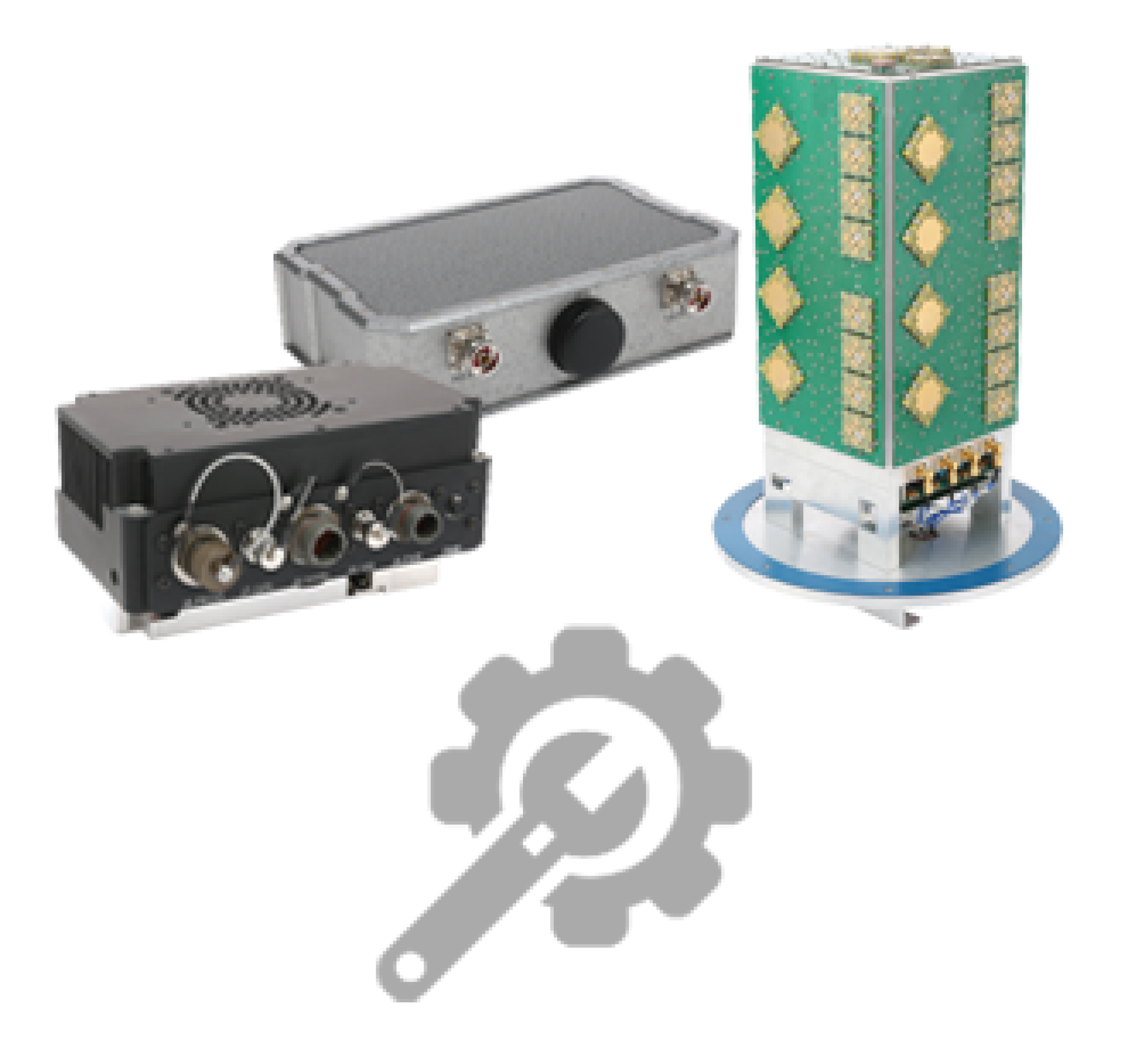

- Customized System Solutions

Latest News

RFcore provides you the latest news, updates and more

New Products

Explore Our Team

We’re looking for gritty and innovative minds to help us build a better and faster world through RF Technology. Come join our team today!

HEAD OFFICE

C-708, Bundang Technopark, 744, Pangyo-ro, Bundang-gu, Seongnam-si, Gyeonggi-do, Republic of Korea, ZipCode : 13510

+82-31-708-7575 (HQ)

SUPPORT

sales@rfcore.com

hongdh@rfcore.com